We have been watching manufacturers replace this for several years V6 engine individually Online configuration. Mercedes-Benz, Jaguar Land Rover and even Mazda for its CX-90, which completely replaces the 4-cylinder engine with an inline 6-cylinder, are now prioritizing this performance configuration. But why? What are the advantages and disadvantages of going in this direction? Let’s go through the topic together.

The beginnings of the in-line six-cylinder engine

The origins of the engine 6 cylinders in linealso known by the term in English just sixdate from the early 20th century. Several manufacturers were already interested in powering vehicles that at the time served primarily as a convenience for wealthier consumers.

Rolls-Royce was one of the first car manufacturers to use it in 1905 in the 30 HP, a model that was replaced by the Silver Ghost the following year. Almost at the same time, the 1906 Ford Model K was powered by an inline six-cylinder engine with a displacement of 6.6 liters.

Mazda inline six-cylinder engine. Photo provided by: Mazda

The in-line six-cylinder engine was also widely used in the aviation industry, especially in Europe. While Mercedes-Benz was the first manufacturer to use its DI engine in an aircraft in 1913, right at the beginning of the First World War, it was BMW that turned it into a lucrative business model.

The Bavarian manufacturer developed the IIIa in 1917 as a drive for a propeller aircraft. It was the very first engine for BMW, which entered automobile marketing in 1933. After that, they continued to rely on the in-line six-cylinder. Today this type of engine is a symbol of the brand. BMW uses it to power a number of vehicles.

Over the years, other automobile manufacturers joined the parade of in-line six-cylinder engines, such as Alfa Romeo in 1921 with the G1 luxury sedan, Mercedes-Benz in 1924 with its M836 3-engine, 9 liters, Opel in 1927 with the 8/ 40 and Volvo in 1929 with its Penta DB engine. This type of engine subsequently spread to almost all automobile manufacturers and is enjoying renewed popularity there.

BMW in-line six-cylinder engine Photo provided by: BMW

The V6 came later

Although some convoluted applications of the V6 engine saw the light of day at Buick and Delahaye in the early 1900s, it was not until 1950 that the first serious application of the principle was widely marketed, under the hood of the Lancia Aurelia.

Especially at the turn of the 1960s, American manufacturers recognized the potential of this engine and multiplied versions from different manufacturers and different models.

This engine then spread in various applications faster than the inline six-cylinder. The V6 has even powered some motorcycles over time. Today it is the most common 6-cylinder engine type in the automotive industry; It’s found everywhere, in midsize sedans and full-size pickup trucks like the Ford F-150. The V6 is still used today for certain racing cars in the IndyCar, GP3 and even Formula 1 series.

Infiniti V6 engine Photo provided by: Infiniti

How does the in-line six-cylinder work?

Unlike the V6, whose name indicates its V-shaped configuration – that is, that it consists of 3 cylinders arranged on each side of the engine – the 6-cylinder is arranged in-line and arranged so that the cylinders are one behind the other Others are lined up in a straight line, as the name suggests.

This configuration also affects the ignition cycle. For example, the piston of a V6 engine is connected directly to its counterpart installed on the other side of the engine. The six in a row will have a slightly more atypical cycle to avoid imbalance.

What are the advantages and disadvantages of an in-line engine versus a V-shaped engine?

Due to its design, the in-line engine usually takes up more space in the longitudinal direction in the engine compartment. For reasons of ease of assembly, but also of weight distribution in the vehicle, manufacturers will primarily use it for longitudinal applications, i.e. for vehicles with rear-wheel drive.

Of course, some manufacturers, such as Volvo, have already installed an inline 6-cylinder engine in a front-wheel drive vehicle, but from a vehicle manufacturing perspective, this approach is usually more complex and costly, not to mention the impact this configuration has on the Weight distribution of a vehicle can have.

Mazda inline six-cylinder engine. Photo provided by: Mazda

Here it loses some of its springs compared to the V6 engine, which is usually more compact and more suitable for different types of vehicles and all types of machinery.

Why do some people prioritize the inline-six over the V6? Firstly, there is the simplicity of this engine, which is very attractive to a manufacturer and allows it to reduce construction costs. Unlike the V6, which is equipped with two cylinder heads, the inline-six only has one, reducing the number of parts required for construction.

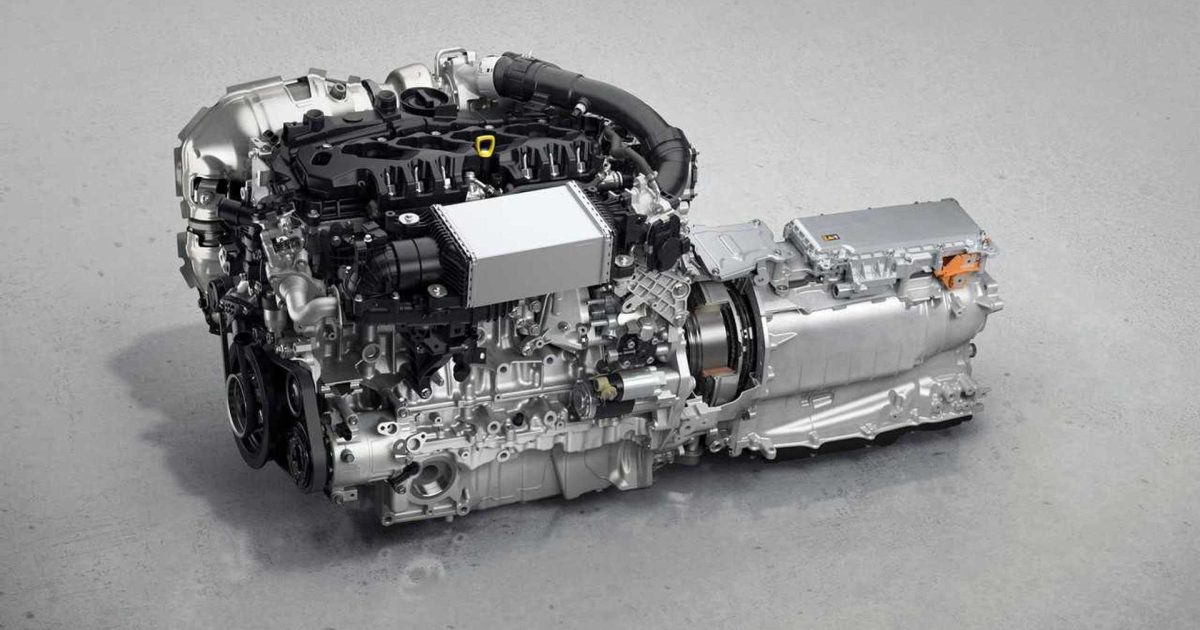

In addition, it is much easier to add accessories such as turbochargers, volumetric compressors (superchargers) and even electrification, such as in particular the mild hybridization system of the Mazda CX-90 from BMW or Mercedes-Benz. The in-line configuration of this engine facilitates the installation of these parts, which in turn reduces its complexity and cost while increasing its reliability.

Maserati V6 engine. Photo provided by: Maserati

A smoother-running engine that produces more torque and fewer CO2 emissions?

In terms of efficiency, the operation of the in-line engine is generally smoother than the V-shaped engine. This property is related to the absence of opposing movements.

Inline engines, especially 6-cylinder engines, are also known for their ability to produce a lot of torque at very low speeds, unlike the V6 which generally needs to rev higher to produce the same amount of torque. Not only does this feature add a superior level of elegance to the vehicle, which is typically valued in luxury vehicles, but it also eliminates the need to run the engine at very high revs to propel the vehicle quickly.

This peculiarity therefore allows it to consume less fuel and, above all, to emit fewer greenhouse gas emissions. With the help of turbocharging, which delivers even more torque at low speeds, not to mention the ability to recycle gases, as well as the addition of a small electric boost, the 6-cylinder engine can become very energy efficient.

Mazda in-line engine. Photo provided by: Mazda

One only has to look at the changes Mercedes-Benz made to the E-Class (W213) from 2017 to 2023 to see the advantages of an inline engine over a V engine for energy efficiency reasons.

While the old 3.0-liter twin-turbo V6 had an average fuel consumption of 10.4 l/100 km and emitted 245 grams of CO2 per kilometer, the consumption of the successor, an in-line six-cylinder with turbocharger and mild hybridization, fell to 9, 3L/100km. 100 km and its greenhouse gas emissions amount to 219 grams of CO2 per kilometer.