Using a combination of nuclear technology and machine learning (ML), a team of scientists at the U.S. Department of Energy’s (DOE) Argonne National Laboratory has made a significant discovery for maintaining the safety and efficiency of a next-generation nuclear reactor type. known as a sodium-cooled fast reactor (SFR).

Main lessons

| Argonne scientists have developed a machine learning system to continuously monitor the SFR cooling system and quickly detect anomalies. |

| The METL facility is a unique test facility designed to safely and accurately test materials and components intended for use in these reactors. |

| The team plans to refine the model to distinguish between real process anomalies and random measurement noise. |

| The combination of nuclear technology and machine learning opens up promising prospects for the future of nuclear energy. |

The role of sodium-cooled fast reactors

An SFR is a type of nuclear reactor that uses liquid sodium to cool its core and efficiently generate carbon-free electricity by splitting heavy atoms.

Although these reactors are not yet in commercial use in the United States, many believe they could transform energy production and help reduce nuclear waste. However, they present challenges, such as maintaining the purity of their sodium coolant at high temperatures. This aspect is crucial to prevent corrosion and blockages in the system.

The contribution of machine learning

To address these challenges, Argonne scientists have developed a new ML system, detailed in a recent article in the journal Energies.

“By harnessing the power of machine learning to continuously monitor and detect anomalies, we are advancing the state of the art in instrument control,” commented Alexander Heifetz, senior nuclear engineer at Argonne and co-author of the paper. “This will represent a breakthrough in the efficiency and cost-effectiveness of nuclear energy systems. »

This is how the ML model works

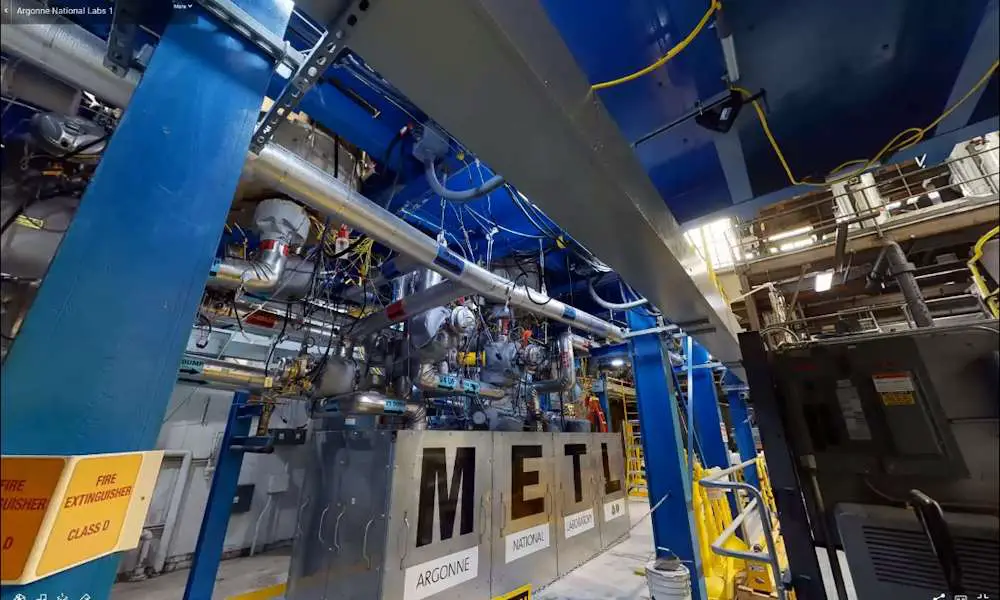

First, the team created an ML model to continuously monitor the cooling system. The model is equipped to analyze data from 31 sensors at the facility METL (Mechanisms Engineering Test Loop) Systems from Argonne that measure variables such as fluid temperatures, pressures and flow rates.

Established in 2010, Argonne’s Mechanism Engineering Test Loop (METL) facility is a medium-sized liquid metal experimental facility that supplies R-grade purified sodium to various experimental test vessels to test components required to operate in a prototypical advanced reactor environment. The experiments carried out at the METL facility contribute significantly to the development of advanced reactors.

The METL facility is a unique test facility designed to safely and accurately test materials and components intended for use in these reactors. It also trains the engineers and technicians (and now ML models) who can help with operation and maintenance.

The Mechanisms Engineering Test Loop facility at Argonne National Laboratory is the largest liquid metal testing facility in the United States. METL tests small and medium-sized components for use in sodium-cooled fast reactors.

A comprehensive system enhanced with ML can enable more robust monitoring and prevent anomalies that could disrupt the operation of a real reactor.

Anomaly detection and future improvements

Second, the team demonstrated the model’s ability to quickly and accurately detect operational anomalies. They put this to the test by simulating a loss-of-coolant type anomaly, characterized by a sudden increase in temperature and flow. The model detected the anomaly about three minutes after it formed. This capability highlights its effectiveness as a security mechanism.

Finally, the research suggests significant improvements for future models. Currently, the model reports any spike that exceeds a predetermined threshold. However, this method could result in false alarms due to random spikes or sensor errors. Not all spikes are anomalies.

The team plans to refine the model to distinguish between real process anomalies and random measurement noise. This includes the requirement that the signal must remain above the threshold for a certain period of time before it is considered an anomaly. They will also incorporate spatial and temporal correlations between sensors into the loss calculation.

synthetic

The combination of nuclear technology and machine learning opens up promising prospects for the future of nuclear energy. Through continuous monitoring and rapid anomaly detection, we can ensure the reliability and durability of sodium-cooled fast reactors and make nuclear energy an even more promising solution for our future energy needs.

Image gallery

Installing the METL

Installing the METL

For better understanding

What is a Sodium Cooled Fast Reactor (SFR)?

An SFR is a type of nuclear reactor that uses liquid sodium to cool its core and efficiently produce carbon-free electricity by splitting heavy atoms.

Why are SFRs not yet used commercially in the United States?

SFRs present challenges such as maintaining the purity of their sodium coolant at high temperatures, which is critical to preventing corrosion and clogging in the system.

Argonne scientists have developed a new machine learning system that continuously monitors the cooling system and quickly detects anomalies, improving the efficiency and safety of SFRs.

What is METL installation and what role does it play?

The METL facility is a unique test facility designed to safely and accurately test materials and components intended for use in these reactors. It also trains the engineers and technicians (and now machine learning models) who can help with operation and maintenance.

What improvements are there for future machine learning models?

The team plans to refine the model to distinguish between real process anomalies and random measurement noise. This includes the requirement that the signal must remain above the threshold for a certain period of time before it is considered an anomaly. They will also incorporate spatial and temporal correlations between sensors into the loss calculation.

[ Rédaction ]